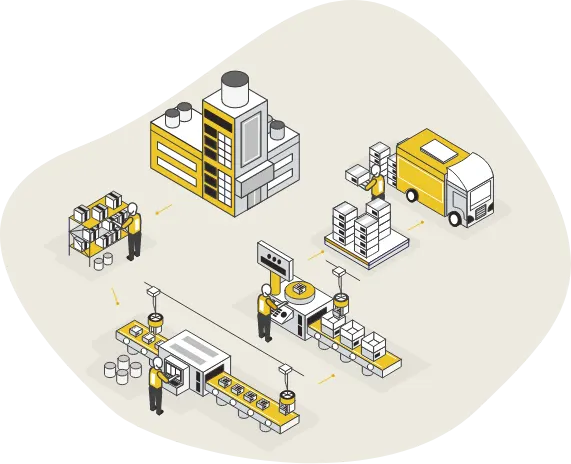

For efficient Production Control and Visibility : Fabrix Manufacturing Execution System (FabrixMES) streamlines operations, improves quality, enhances efficiency and drives profitability.

FabrixMES enables compliance bound manufacturing with close loop quality control and monitoring for defect free production . Production life cycle data of Man , Machine and Material (3M) is captured error free and realtime from Machines and AIDC equipment ,

This data captured at strategic processes helps create the required actionable Insights for a seamless shopfloor operations.

Manufacturing Execution System

is a software that connects, monitors, and controls the complexManufacturing information systems

and Data flow across the production plant. This helps improve the production output by effective execution of manufacturing operations.MES Software

is afunctional information system

that lies between ERP and the process control systems, giving the Manufacturer’s real-time visibility, flexibility, and insight of how to improve the operational efficiency of Manufacturing. They connect multiple sites, factories, and vendors real-time production information and also integrates the automation equipment with business applications. A goodMES System

is a production-oriented software that seamlessly integrates with existing business applications and acts as a conventional ERP for Manufacturing Industry. The result is enhanced visibility, control, and optimization of production processes across the enterprise.Key benefits of an MES include:

- Increased customer satisfaction

- Better regulation compliance

- Improved visibility of supply chain

- Decreased manufacturing cycle time

- Reduced-order lead time

- Reduced labor costs

- Increased equipment efficiency

Manufacturing Execution System

, also calledShop Floor Tracker

, increases visibility and transparency into every aspect of manufacturing operation.

INDUSTRIES WE SERVE

- Aviation & Defence

- Electrical & Electronics Assembly

- Automobile

- Pharma & Surgical

Amongst all domains of the discrete manufacturing industry, Aviation & Defence proves to be the most complex. Stringent compliances , severe quality control, rigid competition, wider supply chains, increasing regulations, dearth of skilled labor are few factors which explain the complexity. While players in this industry aim at reducing costs and increasing qualitative productivity, many projects roll over the pre-fixed time and cost frames resulting in delayed deadlines as well as exceeding budgets.

An efficient execution of the manufacturing process is the need of the hour to wade through such adverse situations and stay active in the business. And this could be achieved only through a competent MES Software.

A well-executed MES System not only helps businesses in stopping unnecessary financial leakages but also increases productivity. Trace and Trace for Non-Confirmance returned material is a much need to the MES for identifying any component , workstation failure issues to recall the entire batch and clear the issues.

Electrical & Electronics Assembly

Manufacturers of the electrical and electronics segment constantly face the need to produce mass quantities at the lowest cost while not compromising on the quality. Other challenging factors include steep price falls, swift technological drifts, increasing demand for custom made products. All such aspects force businesses of this industry to launch high end innovative products at frequent intervals to keep pace with the competition. This scenario demands a continuous, effective and swift assemblies at the shop floor level. Larger batch sizes of components need to be assembled at rapid speeds to generate high quality products at large quantities. To get the processes rolling at such desired levels businesses need to update to cutting edge technologies likeMES Software

which would help their processes roll over at high and effective speeds. We help you achieve such business goals in a cost-effective way. Our MES - the FalconSFT, effectively manages the material and data flow across operations. Your business would gain real-time visibility into the shop floor eliminating wastages and ensuring efficient assemblies. Get a hawk eye on your overall production with our Dashboards, KPI’s reporting. Gain a competitive edge in your industry by choosing the rightMES Software

for your business – the FalconSFT.Automobile

Automobile industry since its inception, has been a challenging industry. With the need to introduce innovative models faster than ever, focusing on key features like safety, quality, fuel efficiency and also being eco-friendly at the same time, has mounted much pressure on the industry and its players than ever. Demanding equal attention on par with the product attributes are areas of logistics and supply chains. With businesses majorly focusing on the product, supply chain and logistics they tend to limp concentrating on elements with equal importance such as inventory status, scrap elimination and fluctuating component costs. An effectiveMES System

like Inventrax’s FalconSFT is needed to manage such gigantic manufacturing tasks effectively and efficiently. As businesses strive to live up to the existing market demand, FalconSFT helps businesses cut down the production costs and helps produce better products faster. Businesses could also benefit through improvised processes, better management of the inventories, improved operational efficacy to name a few.Pharma & Surgical

As one of the most regulated domains of the life sciences industry, the Pharmaceutical & Surgical instruments segment has to adhere to strict standards and even more stringent quality checks. With life style drugs on the rise, pharmaceutical companies need to bid good bye to their traditional R&D cycles (which were both extensive & expensive) to introduce newer products at a faster pace to meet the competition and gain profitability. Other concerns include drug & patent expirations, counterfeiting products etc… The surgical industry as well, is experiencing a shift in its product line with the advent of robotic surgeries gaining momentum around the globe. Businesses involved in this industry are extremely pressurized balancing the - R&D time on newer robotic surgical products, and the need to reduce the time-to-market of such products. In such high volatile market conditions, companies of the Pharma & Surgical industry need effective solutions to survive the competition and stay active in business. An adept tool to achieve this is an effectiveMES Software

. FalconSFT, Inventrax’s innovative MES Software helps you in adapting the swift market fluctuations, respond accordingly and ensure faster ‘product reaches’ to the market before your competition. Our MES System ensures that the items are built according to the product specification and quality. Error free auto data capture is feasible through barcode, RFID and SCADA systems. Effective tracking of all the shop floor activities reduces cycle times.Key Benefits of Our Solution

Floor Activities Visibility

Effective management and real-time visibility of shop floor activities

Resource Optimization

Increase yield along with product quality

Improved Efficiency

Improve operator and machinery efficiencies

Efficient Heterodoxy

Efficient Non-Conformance Management

Data Management

Electronically captures and tracks detailed engineering and operational data

Resources Availability Tracking

Eliminate wastages throughout production, checks for – machine, material, worker, tool availability

Paperless Management

Paperless shop floor and material dispatch management

Accessible in Multiple Systems

Error free auto data capture through barcode , RFID and SCADA systems

Accurate KPI's

Bird’s eye view of overall production with Dashboards, KPI reporting

Data Analytics

Provides historical data analysis and reporting for product and process improvements

Data Accuracy

Rapid, accurate data collection enables error free data collection and access to real-time business intelligence across all areas of production